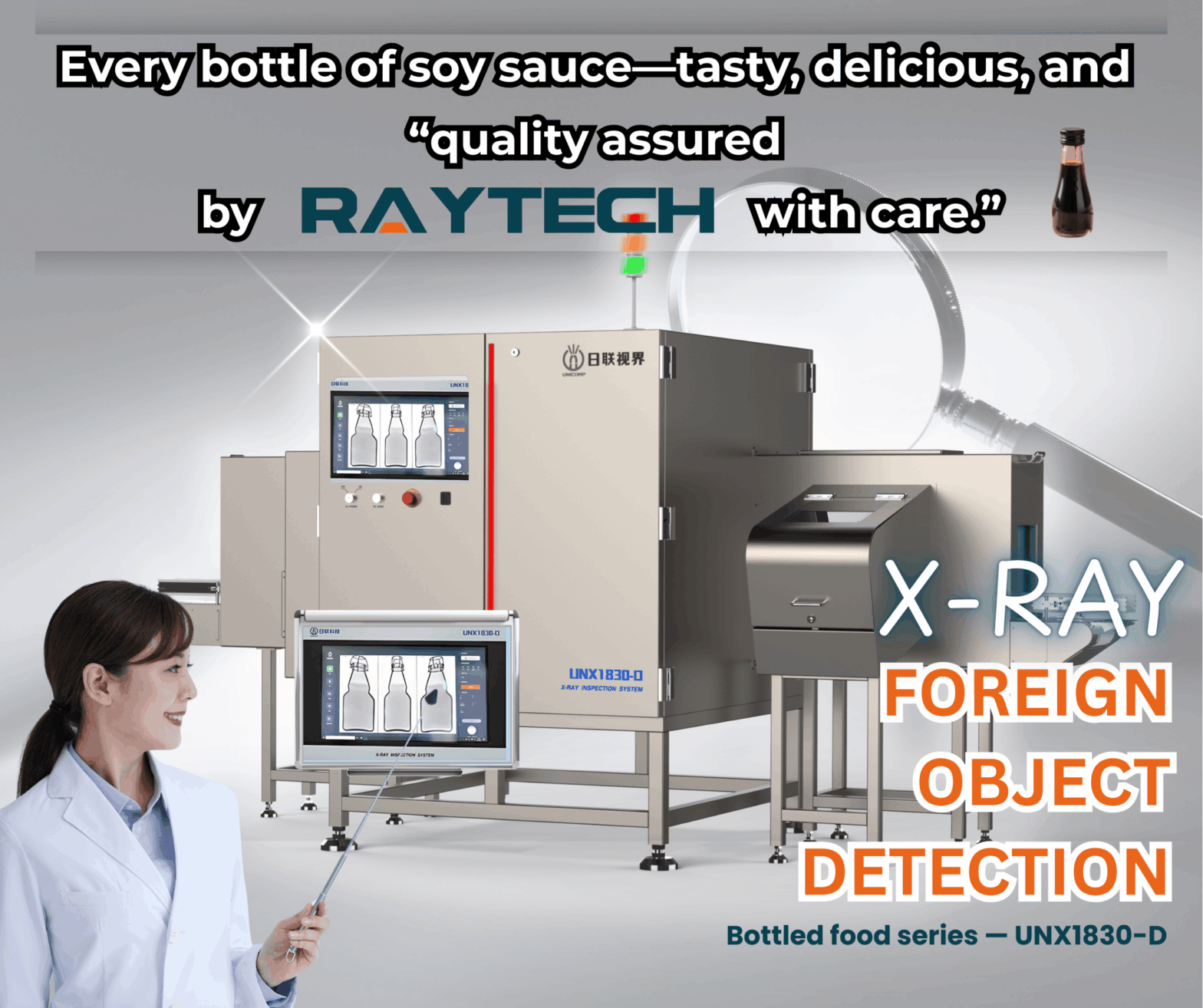

Food safety is a top priority in today’s competitive F&B industry. From moldy grains to small metal fragments, even the slightest contamination can compromise taste, consumer health, and brand trust. Ensuring every product is safe, consistent, and high-quality is essential for protecting both consumers and manufacturers. Ray Tech Malaysia’s parent company, Unicomp Technology Group—widely recognized as an “industrial doctor”—has over 15 years of expertise in non-destructive X-ray inspection. By combining Artificial Intelligence with advanced X-ray technology, Unicomp delivers reliable foreign object detection solutions that help leading food brands worldwide safeguard their products. One example is a global top-five condiment producer, which uses Unicomp’s AI X-Ray Intelligent Inspection System to ensure its soy sauce remains safe, free from contaminants, and trusted by millions of consumers. This system, equipped with 128 high-precision air valves, achieves 100% detection of foreign matter and defective materials, guaranteeing the highest standard of quality. Unicomp’s FOD Series – Tailored for Food Safety With these specialized solutions, manufacturers can detect foreign objects across every type of food product—from raw bulk ingredients to finished packaged goods—ensuring compliance with regulations and building lasting consumer trust. At Ray Tech Malaysia, we are proud to deliver these advanced food inspection systems to the Malaysian market, supporting businesses in their mission to provide safe and high-quality products to consumers.

Author: admin

Ray Tech Malaysia’s Parent Company, Unicomp Technology Group: World-Class AI-Powered X-Ray Solutions in Industrial Inspection

Ray Tech Malaysia is proud to highlight the achievements of our parent company, Unicomp Technology Group—a multinational high-tech enterprise recognized in the industry as an “industrial doctor” for its advanced diagnostic capabilities. With continuous innovation, Unicomp is breaking decades of monopoly in traditional X-ray technology, redefining standards in industrial inspection and establishing itself as a driving force in the global market. On August 29, 2025, Unicomp Technology Group released its mid-year financial report, showcasing strong growth and resilience. The company recorded revenue of 460 million RMB in the first half of the year, representing a 38.34% increase compared to the same period last year. This outstanding performance reflects Unicomp’s commitment to research, development, and the application of AI-powered X-ray solutions that meet the evolving needs of industries worldwide. At Ray Tech Malaysia, we are honored to contribute to this momentum by bringing Unicomp’s cutting-edge inspection technology to the Malaysian market. Together, we remain dedicated to delivering reliable, innovative solutions that empower our customers and strengthen industrial quality assurance.

Selamat Hari Merdeka!

As Malaysians across the nation return to their hometowns to celebrate this meaningful occasion with family and friends, we at Ray Tech Malaysia are reminded of the true spirit of Merdeka—unity, resilience, and trust. These values not only define our nation’s journey but also guide us in the way we serve our customers and partners every day. At Ray Tech Malaysia, a subsidiary of Unicomp Technology Group, we remain committed to delivering excellence in both our products and services. Our goal is to continue supporting Malaysia’s industries with reliable solutions while upholding the principles of integrity and innovation. On this special day, we extend our warmest wishes to all Malaysians. May your journey home be safe, and may your Merdeka celebration be filled with joy, pride, and togetherness. Happy Merdeka Day from all of us at Ray Tech Malaysia.

𝐄𝐱𝐩𝐥𝐨𝐫𝐢𝐧𝐠 𝐒𝐦𝐚𝐫𝐭 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 𝐟𝐨𝐫 𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐧𝐢𝐜𝐬 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 | 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 𝐕𝐢𝐬𝐢𝐭𝐬 𝐉𝐨𝐡𝐨𝐫 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐅𝐚𝐢𝐫 𝟐𝟎𝟐𝟓

On August 27, our team had the opportunity to visit the Johor Industrial Fair 2025 as guests — a valuable chance to see how the industry is tackling quality control challenges in electronics manufacturing, such as hidden solder defects, voids in BGAs , component misalignments, and micro-cracks in PCB assemblies . At Ray Tech Malaysia, we’re proud to support these efforts with Unicomp’s advanced AI-powered X-Ray inspection systems , designed to meet diverse inspection needs across manufacturing scales: 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐀𝐗𝟕𝟗𝟎𝟎 A Compact X-Ray Inspection System optimized for mass production SMT lines. Equipped with AI algorithms, it efficiently detects defects in BGAs, QFNs, and solder joints — providing fast, reliable inspection to maintain production throughput without compromising quality. 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐀𝐗𝟖𝟐𝟎𝟎𝐌𝐚𝐱 A Versatile Offline Inspection System perfect for medium to high-volume PCB assembly lines. It offers comprehensive inspection capabilities for fine-pitch components, supporting real-time defect analysis and factory traceability integration for smart manufacturing. 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐂𝐗𝟑𝟎𝟎𝟎 A Compact Desktop X-Ray Inspection and Counter Machine suited for R&D labs, prototyping, and small-batch production. Its high-resolution imaging and user-friendly interface allow detailed inspection and failure analysis of PCBs and electronic modules. 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐀𝐗𝟗𝟏𝟎𝟎𝐌𝐚𝐱 A High End Industrial X-Ray System designed for large, thick, or dense electronic assemblies like power modules and automotive boards. Featuring a powerful X-Ray source (130kV), it delivers clear imaging for quality control of complex and large-format products. These cutting-edge systems enable manufacturers to detect hidden defects early, improve yields, and ensure product reliability — all while embracing Industry 4.0 principles with AI-driven analytics and smart data management. We’re excited about the future of electronics manufacturing and the role these technologies play in Malaysia’s industrial advancement!

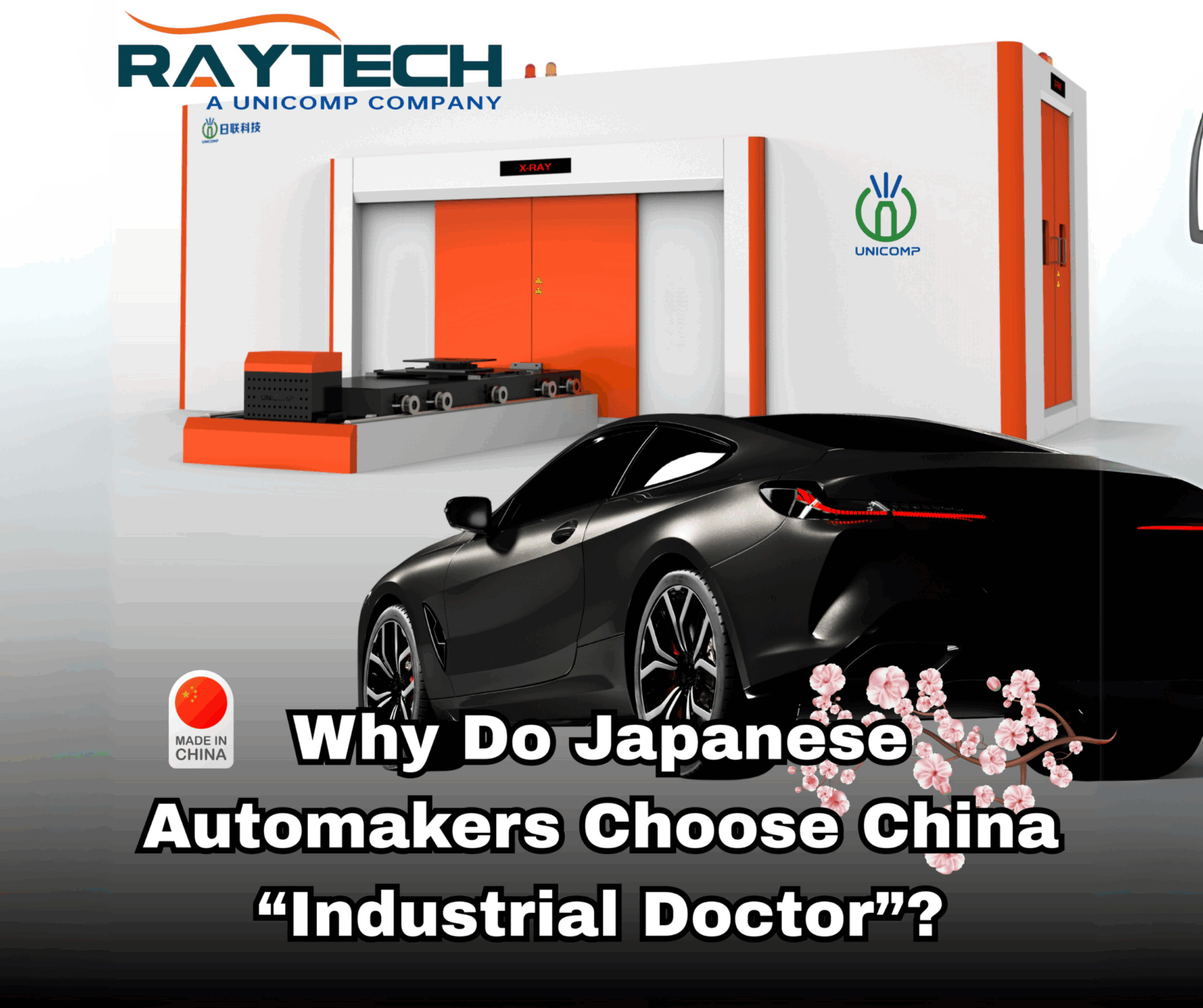

𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐒𝐦𝐚𝐫𝐭 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐆𝐨𝐞𝐬 𝐆𝐥𝐨𝐛𝐚𝐥: 𝐖𝐡𝐲 𝐃𝐨 𝐉𝐚𝐩𝐚𝐧𝐞𝐬𝐞 𝐀𝐮𝐭𝐨𝐦𝐚𝐤𝐞𝐫𝐬 𝐂𝐡𝐨𝐨𝐬𝐞 𝐂𝐡𝐢𝐧𝐚’𝐬 “𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐃𝐨𝐜𝐭𝐨𝐫”?

As the demand for lightweight vehicle bodies continues to rise, integrated die-casting technology is reshaping the development of Japan’s automotive industry. Consequently, the need for fast and precise non-destructive testing has become especially critical. Recently, Ray Tech Malaysia’s parent company, Unicomp leveraged its advanced technological advantages and outstanding service capabilities in integrated die-casting inspection to win recognition from a leading automotive parts manufacturer. The company successfully delivered its X-ray intelligent inspection equipment for integrated die-cast parts to Japan. But why would Japanese companies—renowned worldwide for precision manufacturing —choose to import “integrated die-casting inspection equipment” from China? 𝐔𝐧𝐯𝐞𝐢𝐥𝐞𝐝: 𝐓𝐡𝐞 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐔𝐍𝐓𝟏𝟔𝟎𝐃 𝐏𝐀𝐑𝐓 𝟎𝟏 – 𝐅𝐫𝐨𝐦 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭 𝐭𝐨 𝐃𝐞𝐥𝐢𝐯𝐞𝐫𝐲: 𝐙𝐞𝐫𝐨 𝐅𝐫𝐢𝐜𝐭𝐢𝐨𝐧 The requirements raised by the Japanese client had already been standardized in Unicomp’s R&D team . 𝐏𝐫𝐨𝐯𝐞𝐧 𝐛𝐲 𝐌𝐢𝐥𝐥𝐢𝐨𝐧𝐬 𝐨𝐟 𝐄𝐱𝐩𝐞𝐫𝐢𝐞𝐧𝐜𝐞𝐬 Unicomp has worked with numerous leading enterprises, conducting inspections on over one million die-cast products. With this wealth of experience, Unicomp has built a highly standardized solution for integrated die-casting inspection. After comparing multiple inspection solutions worldwide, the detail-oriented Japanese automaker found Unicomp’s X-Ray inspection equipment to deliver results far beyond expectations. 𝐌𝐚𝐱𝐢𝐦𝐮𝐦 𝐒𝐚𝐟𝐞𝐭𝐲 𝐢𝐧 𝐄𝐯𝐞𝐫𝐲 𝐃𝐞𝐭𝐚𝐢𝐥 Unicomp UNT160D X-ray Inspection Equipment is equipped with multiple safety protection systems . Its radiation level is ≤1 μSv/h (only 1/10 of the international safety standard and fully compliant with EU standards). The lead cabin uses a “steel–lead–steel” sandwich structure, ensuring zero deformation throughout its service life. Additionally, the cabin is equipped with secure door locks and dual mechanical–electrical interlock protections to guarantee absolute operator safety . 𝐏𝐀𝐑𝐓 𝟎𝟐 – 𝐀𝐈-𝐏𝐨𝐰𝐞𝐫𝐞𝐝 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 𝐰𝐢𝐭𝐡 𝟗𝟗.𝟗% 𝐀𝐜𝐜𝐮𝐫𝐚𝐜𝐲 To meet the needs of Japanese automakers inspecting various die-cast parts, Unicomp’s ADR (Automatic Defect Recognition) function provides a perfect match. Unicomp’s self-developed industrial X-ray digital imaging software , enhanced by AI algorithms, can automatically interpret imaging results, perform objective evaluations , and return detailed “pass/fail” feedback. Extensive Case Database for Quick Adaptation The software integrates a massive database, enabling AI to recognize defects automatically without requiring extensive retraining, making it adaptable to a wide variety of products. Smarter with Every Use Unicomp software has strong self-learning capabilities. For specific customer products, the ADR system’s recognition rate and accuracy can reach up to 99.9% as data accumulates. Versatile and Highly Compatible The software is compatible with multiple materials and capable of detecting various defect types. It places no special requirements on shape or positioning, fully meeting Japanese automakers’ diverse inspection needs. It also supports Chinese, Japanese, and English interfaces, freely selectable in the software settings. 𝐏𝐀𝐑𝐓 𝟎𝟑 – 𝐒𝐦𝐚𝐫𝐭𝐞𝐫 𝐰𝐢𝐭𝐡 𝐄𝐯𝐞𝐫𝐲 𝐔𝐬𝐞 Unicomp software continues to improve with accumulated data, pushing accuracy to new heights. With multi-material compatibility and flexibility in defect detection, it ensures seamless integration for Japanese automakers’ diverse inspection demands. From Made in China to Trusted Worldwide, Unicomp’s smart inspection equipment is redefining global quality standards.

𝐆𝐥𝐨𝐛𝐚𝐥 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐲 𝐔𝐩𝐠𝐫𝐚𝐝𝐞 | 𝐀𝐈-𝐃𝐫𝐢𝐯𝐞𝐧 𝐒𝐦𝐚𝐫𝐭 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧

August 11, 2025 — Ray Tech Malaysia’s parent company, Unicomp Technology Group officially launched its AI Industrial Inspection R&D Center in Shanghai, focused on advancing AI-powered intelligent detection technology. A strategic cooperation framework agreement was signed with Zhangjiang Group, strengthening the fusion of AI and industrial smart inspection. 𝐁𝐮𝐢𝐥𝐝𝐢𝐧𝐠 𝐚 𝐕𝐞𝐫𝐭𝐢𝐜𝐚𝐥 𝐀𝐈 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐒𝐭𝐫𝐨𝐧𝐠𝐡𝐨𝐥𝐝 Our new R&D center is dedicated to developing specialized vertical AI models for industrial inspection — enabling us to see clearer , detect faster , and judge with precision . With a strengthened AI research team, we are accelerating our transformation from a traditional equipment manufacturer to an AI-driven global solutions provider, solidifying our leading position in industrial X-ray AI intelligent inspection. 𝐀𝐈 𝐈𝐧𝐭𝐞𝐫𝐧𝐚𝐭𝐢𝐨𝐧𝐚𝐥𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐓𝐡𝐫𝐨𝐮𝐠𝐡 𝐄𝐜𝐨𝐬𝐲𝐬𝐭𝐞𝐦 𝐄𝐦𝐩𝐨𝐰𝐞𝐫𝐦𝐞𝐧𝐭 Leveraging Zhangjiang Science City’s innovation ecosystem and global resources, we aim to integrate technology, talent, and markets worldwide: Technology Fusion — Combining Zhangjiang’s innovation momentum with Unicomp’s industrial inspection expertise for deeper AI + inspection integration. Talent Network — Attracting top R&D talent through global recruitment and enhancing localized services in Europe, the U.S., and Asia. Ecosystem Synergy — Expanding global cooperation in new energy vehicles, semiconductors, and more. 𝐎𝐮𝐫 𝐀𝐈-𝐏𝐨𝐰𝐞𝐫𝐞𝐝 𝐗-𝐑𝐚𝐲 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: Semicon & Electronic Inspection, AX9100MAX — High-precision 3D CT X-ray system for semiconductor packaging & microelectronics. Foreign Object Detection, UNX4015-N — Compact, high-resolution PCB & SMT inspection solution with AI defect recognition. Diecasting Inspection Equipment, UNC160 — Fast, accurate battery & cylindrical cell inspection for the EV industry. Counting Machine, AX7900 — Counting component X-ray inspection with deep AI integration. 𝐆𝐥𝐨𝐛𝐚𝐥 𝐀𝐈 𝐑&𝐃 𝐂𝐨𝐥𝐥𝐚𝐛𝐨𝐫𝐚𝐭𝐢𝐨𝐧 Our Shanghai AI R&D Center will work alongside Unicomp’s research institute and overseas centers in the U.S. and Hungary to build a global AI strategy network — exporting Chinese technology to the world and delivering “China Technology, Global Service”. Contact us should you have any further inquiry.

𝐑𝐢𝐬𝐢𝐧𝐠 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐃𝐞𝐦𝐚𝐧𝐝 𝐈𝐦𝐦𝐞𝐝𝐢𝐚𝐭𝐞 𝐗-𝐫𝐚𝐲 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 𝐚𝐭 𝐀𝐒𝐄𝐀𝐍𝐓𝐎𝐌 𝟐𝟎𝟐𝟓

On 12 Aug 2025, Ray Tech Malaysia was honored to attend The 12th Annual Meeting of the 𝐀𝐒𝐄𝐀𝐍 𝐍𝐞𝐭𝐰𝐨𝐫𝐤 𝐨𝐟 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐨𝐫𝐲 𝐁𝐨𝐝𝐢𝐞𝐬 𝐨𝐧 𝐀𝐭𝐨𝐦𝐢𝐜 𝐄𝐧𝐞𝐫𝐠𝐲 (𝐀𝐒𝐄𝐀𝐍𝐓𝐎𝐌) on 12th August 2025 at Renaissance Johor Bahru Hotel, Malaysia. During the event, we shared insights on our AI-Powered Industrial X-ray technology, exchanged best practices, and contributed to collaborative discussions in a vibrant and positive atmosphere. During the event, we shared insights on our AI-Powered Industrial X-ray technology, exchanged best practices, and contributed to collaborative discussions in a vibrant and positive atmosphere. At Ray Tech Malaysia, we help industries solve critical challenges with precision X-ray inspection technology: • In the 𝐒𝐞𝐦𝐢𝐜𝐨𝐧 & 𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐧𝐢𝐜 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲, we address micro-defects, voids, and die alignment for miniaturized, high-performance components. • In 𝐍𝐨𝐧-𝐃𝐞𝐬𝐭𝐫𝐮𝐜𝐭𝐢𝐯𝐞 𝐓𝐞𝐬𝐭𝐢𝐧𝐠 (𝐍𝐃𝐓), we enable structural assessment without damaging vital casting materials or parts. • In 𝐅𝐨𝐫𝐞𝐢𝐠𝐧 𝐎𝐛𝐣𝐞𝐜𝐭 𝐃𝐞𝐭𝐞𝐜𝐭𝐢𝐨𝐧, we provide solutions to locate unwanted contaminants in food manufacturing and packaging lines. • For the 𝐋𝐢𝐭𝐡𝐢𝐮𝐦 𝐁𝐚𝐭𝐭𝐞𝐫𝐲 𝐒𝐞𝐜𝐭𝐨𝐫, we help detect internal short circuits, swelling, and potential fire hazards before they escalate. 𝐀𝐗𝟗𝟏𝟎𝟎𝐌𝐀𝐗: Our high-resolution X-ray inspection system, designed for ultra-precise imaging of complex components. Ideal for semiconductor packaging, BGA/void analysis, and battery cross-sectional inspection. Large scanning area Sub-micron resolution 2D, oblique view & real-time imagin 𝐗𝟖𝟐𝟎𝟎𝐌𝐀𝐗: A compact, high-efficiency system perfect for high-speed production lines in semicon and electronic applications. Fast throughput User-friendly interface Reliable automation compatibility

Post-Event Reflection: Advancing Food Safety with AI-Powered X-Ray Technology at MIFB 2025

The Malaysia International Food & Beverage (MIFB) 2025 exhibition has officially concluded, and what an exciting and insightful event it was for the Ray Tech Malaysia team. Held at the Kuala Lumpur Convention Centre from 30 July to 1 August, MIFB once again proved to be a vital platform for innovation, collaboration, and progress within the F&B industry. We were proud to showcase our latest AI-powered X-ray inspection systems, designed to elevate food safety standards and support manufacturers in overcoming growing industry challenges. Tackling Real-World Challenges in Food Safety As consumer expectations rise and global food regulations become increasingly stringent, the demand for reliable, non-destructive inspection systems is higher than ever. Food producers face significant issues including: Our presence at MIFB 2025 focused on offering practical, scalable solutions to these critical challenges. Featured Technology at Our Booth Visitors to Hall 4, Booth 4512 had the opportunity to experience firsthand our latest foreign object detection equipment. These systems are built to provide high-speed, accurate, and automated inspection — all powered by advanced AI algorithms: These models offer: Industry-Driven, Globally Proven Ray Tech Malaysia is proud to be a subsidiary of Unicomp China, a leader in X-ray inspection systems across multiple industries. While our MIFB focus was on food safety, our solutions extend to: A Heartfelt Thank You To all the attendees, partners, and industry professionals who visited our booth — thank you. Your questions, feedback, and shared experiences are what continue to drive our innovation forward. MIFB 2025 was more than an exhibition; it was a reminder of the collective responsibility we hold in ensuring food safety and quality from farm to fork.

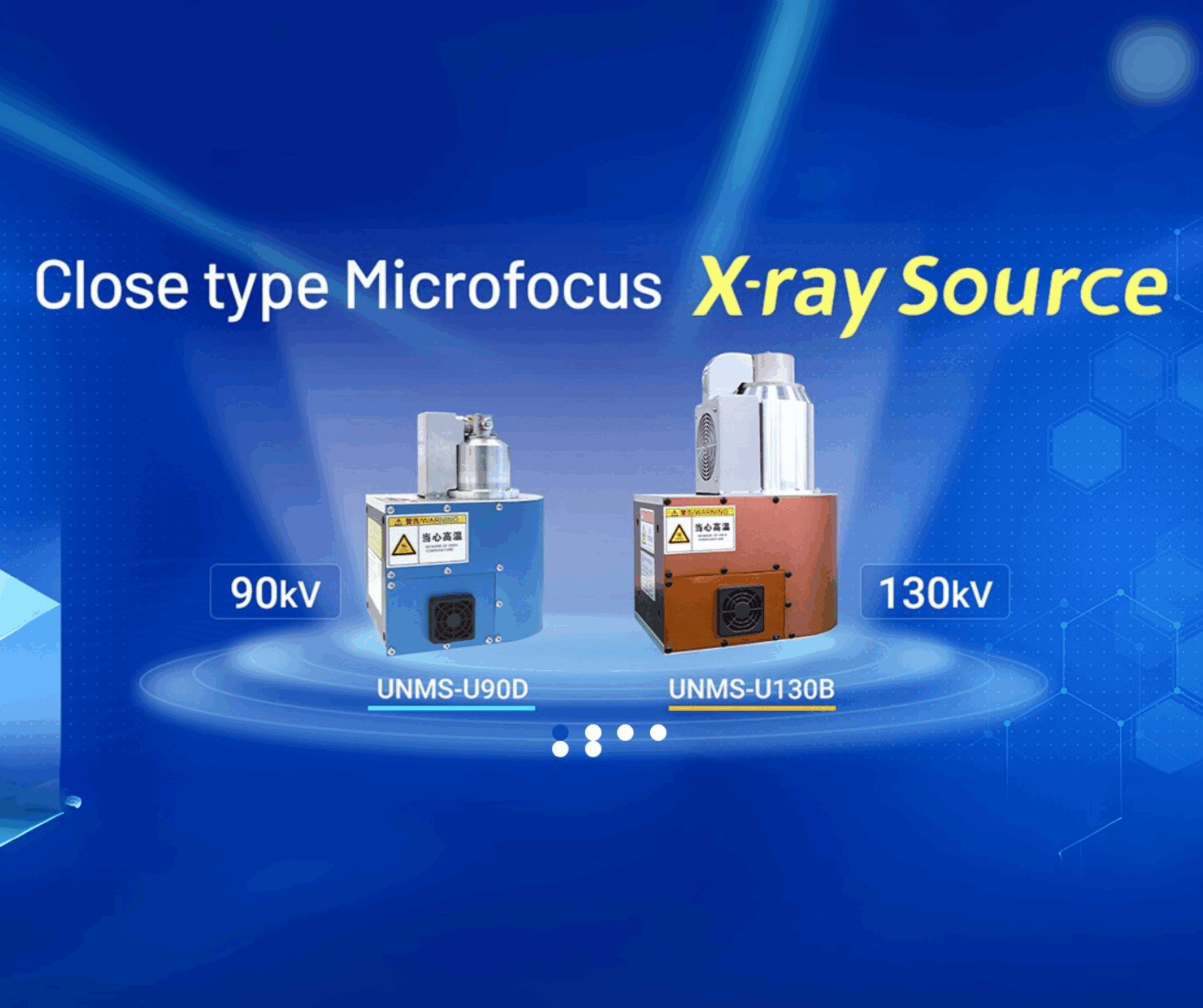

Illuminating Precision: Unicomp’s Breakthrough in AI-Powered X-Ray Source Technology for Semiconductor, Electronics, Die Casting, Lithium Battery, and Foreign Object Detection

In today’s high-tech manufacturing landscape, critical industries such as semiconductors, electronics, die casting, lithium batteries, and food safety face increasing challenges: Unicomp Reveals for the First Time: The Secrets Behind Its Self-Developed X-Ray Source The X-ray tube source — the “heart” of industrial inspection — has long been dominated by foreign manufacturers. This dependence has hindered China’s advancements in semiconductor nano-defect detection and new energy battery quality control, becoming a critical bottleneck in high-precision manufacturing. Now, for the first time, Unicomp Technology unveils the full journey from R&D to mass production of its self-developed X-ray sources. After a decade of relentless innovation, Unicomp has successfully developed a full range of self-produced 90–180kV closed-tube thermionic microfocus X-ray sources. These are now in mass production and being globally deployed, casting light into every corner of intelligent manufacturing. 1.) Unveiling the Core Technologies Four Breakthrough Core Technologies: The UNMS series X-ray sources utilize sophisticated mathematical models and simulations (electric/magnetic fields, thermodynamics) to optimize X-ray generation processes. This forms the technological backbone for high-precision industrial applications. The R&D process spans complex fields: atomic physics, vacuum science, materials engineering, electromagnetics, electron optics, and thermal processing. For instance, rare earth materials—critical to performance—pose challenges due to their structural sensitivity and scarcity, requiring cross-disciplinary breakthroughs in material design and substitution. 2.) The Trillion-Electron-Volt Production Journey At Unicomp, mass production only begins when the yield rate reaches 100%. With an internal penetration rate exceeding 95%, over 5,000 units of the UNMS series have been delivered globally—earning high praise for exceeding the performance of imported models. Mass production required overcoming key challenges in material purity, precision manufacturing, and vacuum sustainability—supported by 100+ tightly controlled process checkpoints. Custom-built high-end equipment—including ultra-high vacuum systems and laser cutters—supports Unicomp’s smart, standardized production line for high-precision tube sources. Precision Assembly Highlights: Each X-ray source includes an integrated digital control module with software interface, enabling real-time monitoring of power, temperature, and error diagnostics, and ensuring safety interlocks with inspection systems. 3.) A Rare Full-Chain R&D Team Unicomp has cultivated a world-class R&D team of nearly 200 professionals, with R&D investment exceeding 11% of annual revenue. The team covers the full value chain of X-ray source development—one of the few such capabilities globally. Unicomp actively participates in national-level science and technology initiatives (e.g., “02 Program,” “863 Program,” and Major Instrument Projects by the Ministry of Science and Technology) and has led the drafting of multiple national and industry standards. The company holds over 500 domestic and international patents. The team has now mastered core technologies such as glass-ceramic substrate modification and rare-earth metal infiltration, supporting large-scale production of 90–180kV microfocus sources. 4.) A Full-Scale Intelligent Inspection Ecosystem From breaking foreign monopolies to achieving international leadership, the story of Unicomp’s X-ray source is a tale of a decade-long journey to domestic innovation—and a driving force in intelligent manufacturing. By integrating “X-ray source + AI algorithm + inspection platform,” Unicomp has built a full-stack industrial inspection ecosystem. The internally closed-loop system ensures 100% zero-defect quality in every new-generation tube that enters the market. With AI-driven precision, Unicomp’s technology powers inspection from nanometer-scale wafers to multi-ton automotive castings. Applications span: It is also expanding into food, aerospace, and pharmaceutical safety—becoming an essential driver of high-end intelligent manufacturing. 5.) Advancing the Frontiers of Imaging Looking ahead, Unicomp will continue to focus on X-ray source innovation with several key goals: After 5 years of focused development, Unicomp has achieved batch production of nanofocus open-tube X-ray sources, which are gaining strong traction among semiconductor and IC clients.(Open-tube sources maintain vacuum with an external pump and offer smaller focal spots than closed tubes—better suited for high-end research and detection.) 6.) Embarking on a Global Mission Rooted in full-stack self-development, Unicomp has achieved complete autonomy over materials, processes, and production equipment, covering the entire industrial chain for high-performance X-ray sources. Its strategic roadmap now focuses on: Through a global manufacturing network and multi-modal technology integration, Unicomp is emerging as a world-class leader in high-precision industrial inspection, reshaping China’s global competitiveness in advanced equipment. “From solitary breakthroughs in the lab to the full force of mass production, a beam of light cuts through.What we see is not just a defect, but the backbone of a nation’s industrial might.The light forged by a thousand trials now becomes the eternal fire that illuminates the future of Chinese manufacturing.”

The 19th Shanghai International Die Casting & Nonferrous Foundry Exhibition | Unicomp Technology Group’s CT Intelligent Inspection Solution Tackles Internal Casting Defect Challenges

July 16, 2025 – The 19th Shanghai International Die Casting and Nonferrous Foundry Exhibition officially opened at the Shanghai New International Expo Centre. As a premier global event in the die casting industry, the exhibition brings together cutting-edge technologies and groundbreaking innovations from around the world. 01 Addressing Industry Pain Points | Breaking Through Internal Defect Detection Barriers During the die casting process, accurate detection of internal defects—such as porosity, shrinkage, and cracks—is critical for ensuring product quality. However, this remains a recognized technical challenge in the industry. Traditional inspection methods have notable limitations: 02 Intelligent CT Solution | A Full-Stack Detection Approach Ray Tech Malaysia’s parent company, Unicomp Technology Group’s showcased solution integrates high-precision X-ray computed tomography (CT) with AI-driven algorithms, offering the following core capabilities: 2.1 3D Imaging Visualization Using high-resolution X-ray scanning, the system rapidly reconstructs a complete 3D model of the workpiece’s internal structure. It clearly visualizes various internal defects—such as porosity, inclusions, and cracks—while accurately locating them in 3D space. 03 Technology Showcase Draws Attention | Dynamic On-Site Engagement On the opening day, Unicomp Technology Group’s booth attracted a large number of technical professionals and decision-makers across the die casting supply chain. The technical team engaged in in-depth discussions with visitors, offering live equipment demonstrations and detailed explanations of application scenarios and pain point solutions. According to public information, Unicomp Technology has a strong track record in the X-ray inspection field, with over 600 core patents and intellectual property certifications. Its solutions are deployed in more than 70 countries and regions, with over 30,000 successful application cases to date. Unicomp Technology Group cordially invites all die casting professionals to connect and collaborate. We remain committed to advancing quality inspection technologies, helping manufacturers enhance precision and efficiency in quality control, and strengthening global competitiveness. Let’s explore innovations and shape the future of the industry—together.