We are proud to witness another key milestone in our global journey — the official opening of Unicomp’s Chongqing Branch, further strengthening our footprint in China’s high-tech manufacturing hub. On the day of the opening ceremony, government representatives, industry experts, business partners, and supply chain stakeholders gathered to envision a shared future of Unicomp development. According to the Chairman of Unicomp Technology (Group), Dr. Liu stated that the commencement of operations at the Chongqing branch will provide stronger and more reliable technical support for quality control and safety inspections across various industries. With a global “3+3” industrial layout—three bases in China and three overseas—Unicomp is now poised for a new leap forward from this thriving land of Chongqing. CEO, Unicomp Technology (Group), Ye Jun Chao introduced the Chongqing Industrial Park, strategically located in Bishan, with a functional layout comprising: • Core Component Intelligent Manufacturing Zone • Flexible Production Lines • AI Inspection Laboratory • Supply Chain Collaboration Center The park focuses on high-end manufacturing, with production capacity for core products expected to grow rapidly, accompanied by significant technological iteration and breakthroughs in cutting-edge areas. Director, Unicomp Research Institute, Dr. Zhang presented several new products, highlighting advancements in core components, complete systems, and software, showcasing Unicomp’s forward-thinking R&D capabilities. The Bishan District government also introduced the current state and investment environment of Bishan’s industrial development. Unicomp Technology Group signed a strategic cooperation agreement with the Chongqing Institute for Advanced Energy Storage Materials and Equipment, led by Academician Pan Fusheng. Together, they will focus on cutting-edge fields such as: • High-performance lightweight materials • Magnesium-based energy storage materials • Next-generation battery technologies Highlights of the Chongqing Branch: • Total Area: Over 75,000 m² • Facilities: Provincial-level technology/engineering centers and academician workstations • Focus: • NDT (Non-Destructive Testing) solutions across the general industrial field • Cutting-edge technologies such as 3D/CT imaging, machine vision, AI, and image processing algorithms This will support Unicomp’s rapid business growth and its “multi-dimensional strategic upgrade.” Relying on Chongqing’s strong smart equipment manufacturing cluster, the base will synergize with upstream and downstream partners to build a closed-loop industrial ecosystem from: R&D → Scenario-Based Applications → Supply Chain Collaboration. This ecosystem aims to contribute to the formation of China’s intelligent inspection equipment industry circle, strengthening Unicomp’s market leadership and expanding its competitive edge. Currently, Unicomp Technology Group operates six major manufacturing and R&D centers worldwide, covering over 130,000 m² in total.

Author: admin

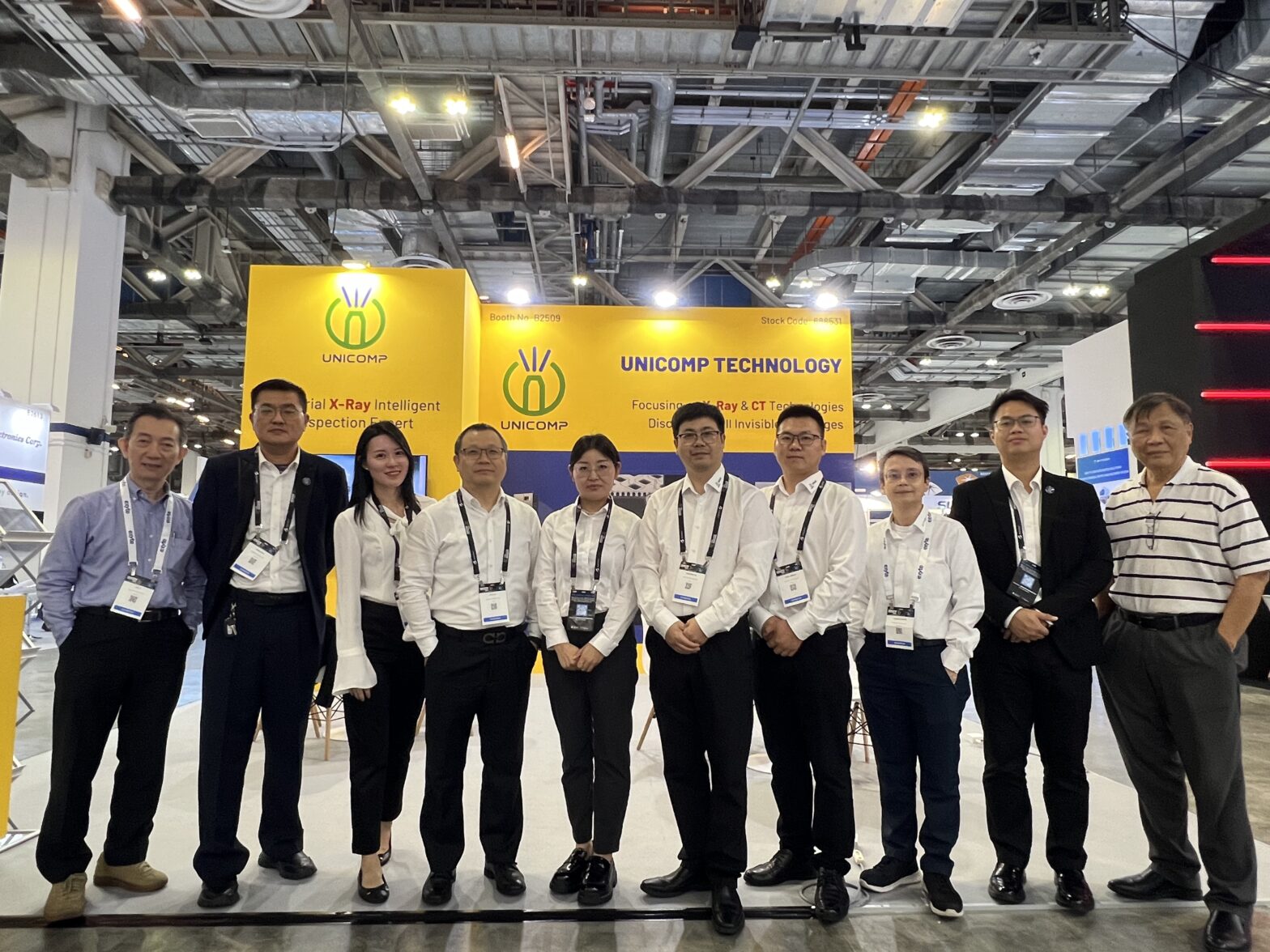

Thank You for Visiting Unicomp at SEMICON SEA Singapore 2025

We would like to extend our sincere appreciation to everyone who visited the Unicomp booth at SEMICON Southeast Asia 2025 in Singapore. It was a pleasure to connect with industry leaders, partners, and innovators throughout the event. At this year’s show, we proudly showcased our latest advancements in AI-powered X-Ray Inspection Solutions, designed to meet the evolving demands of the semiconductor and electronics manufacturing sectors. From enhanced precision in defect detection to improved automation capabilities, our technologies continue to push the boundaries of quality control and production efficiency. The exhibition provided an excellent platform for engaging in meaningful conversations, exploring new business opportunities, and strengthening collaborations with both existing and new partners. We were inspired by the enthusiasm and forward-thinking perspectives shared across the industry, and we are grateful for the positive feedback we received on our solutions. Unicomp remains committed to innovation and excellence, and we look forward to building on the momentum from SEMICON SEA as we continue to support our customers worldwide with intelligent, high-performance inspection systems. Thank you once again for your support and partnership. We are excited for what lies ahead and look forward to seeing you at our next event. Stay connected — innovation continues with Unicomp.

𝐓𝐡𝐞 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 𝐓𝐫𝐚𝐝𝐞 𝐅𝐚𝐢𝐫 𝐢𝐧 𝐆𝐞𝐫𝐦𝐚𝐧𝐲 | 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐒𝐡𝐨𝐰𝐜𝐚𝐬𝐞𝐬 𝐀𝐈+𝐗-𝐑𝐚𝐲 𝐒𝐦𝐚𝐫𝐭 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐒𝐲𝐬𝐭𝐞𝐦 𝐨𝐧 𝐭𝐡𝐞 𝐆𝐥𝐨𝐛𝐚𝐥 𝐒𝐭𝐚𝐠𝐞

The 37th edition of the Control Trade Fair was successfully concluded on May 6–9, 2025 at the Stuttgart Exhibition Cente The Control Trade Fair for Quality Assurance and Measuring Instruments in Stuttgart, Germany, was launched in 1987 and is one of the most renowned exhibitions organized by Schall Exhibitions. As a premier event in the field of quality control and precision instrumentation, this year’s exhibition featured “AI” as a core theme, spotlighting cutting-edge technologies and products in non-contact measurement, 3D metrology, optoelectronics, and laser-based inspection. At this year’s event, Unicomp Technology (Booth No. 9202-2, Hall 9) presented its AX9100MAX Intelligent X-Ray Inspection System, alongside its fully self-developed micro-focus X-ray source technology, introducing a new paradigm of “end-to-end, zero-blind-spot, adaptive” quality control for the global electronics manufacturing and semiconductor industries.

𝐌𝐞𝐞𝐭 𝐎𝐮𝐫 𝐏𝐚𝐫𝐞𝐧𝐭 𝐂𝐨𝐦𝐩𝐚𝐧𝐲, 𝐔𝐍𝐈𝐂𝐎𝐌𝐏 𝐚𝐭 𝐒𝐄𝐌𝐈𝐂𝐎𝐍 𝐒𝐨𝐮𝐭𝐡𝐞𝐚𝐬𝐭 𝐀𝐬𝐢𝐚 𝟐𝟎𝟐𝟓!

From May 20–22, 2025, the Sands Expo & Convention Centre in Singapore will become the epicenter of semiconductor innovation—and we’re thrilled to invite you to Booth B2509 to meet our parent company, UNICOMP. Whether you’re an engineer, operations manager, or quality-control specialist, this is your chance to see first-hand how advanced X-ray inspection can elevate your production process. Event Details About UNICOMP UNICOMP—headquartered in Wuxi, China—is the parent company of Ray Tech Malaysia and a globally recognized leader in X-ray inspection technology. With a commitment to precision and reliability, UNICOMP’s systems serve a diverse range of industries: This international footprint has cemented UNICOMP as a hallmark brand in non-destructive testing and X-ray inspection worldwide. What We’re Showcasing At SEMICON SEA 2025, UNICOMP will debut two flagship inspection systems designed to meet the most demanding production requirements: 1. CX3000 R2R An inline X-ray solution optimized for counterfeit component detection on reel-to-reel assembly lines. Engineered for high throughput without compromising accuracy, the CX3000 R2R identifies hidden defects and ensures component authenticity—helping you safeguard product quality and protect your brand. 2. AX8300S Plus A 2.5D X-ray inspection system built for complex surface-mount technology (SMT) and printed circuit board assembly (PCBA) applications. With advanced imaging algorithms and precise defect-analysis tools, the AX8300S Plus delivers the insights you need to boost production reliability and reduce rework. Why Visit Us? Don’t miss this opportunity to explore the future of smart manufacturing. We look forward to welcoming you to Booth B2509—drop by, say hello, and discover why UNICOMP is the global force in X-ray inspection technology!

𝐆𝐫𝐚𝐧𝐝 𝐎𝐩𝐞𝐧𝐢𝐧𝐠 𝐈𝐧𝐯𝐢𝐭𝐚𝐭𝐢𝐨𝐧 𝐨𝐧 𝟏𝟑𝐭𝐡 𝐉𝐮𝐧𝐞 | 𝐎𝐮𝐫 𝐏𝐚𝐫𝐞𝐧𝐭 𝐂𝐨𝐦𝐩𝐚𝐧𝐲, 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐂𝐡𝐨𝐧𝐠𝐪𝐢𝐧𝐠 𝐍𝐞𝐰 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐏𝐚𝐫𝐤

Date: 13th June 2025 Location: Chongqing, China Dear Valued Customers and Distribution Partners, We are thrilled to announce the grand opening of our Unicomp Chongqing New Industrial Park, a strategic hub dedicated to the development and production of non-destructive testing (NDT) 2.5D and CT/3D X-ray inspection Equipments. This new facility marks a significant step in Unicomp Technology’s mission to lead the global market in intelligent inspection solutions. Specialized in NDT systems, our Chongqing factory integrates advanced R&D, automated production, and high-precision assembly capabilities, ensuring world-class quality and performance across industries such as automotive, aerospace, casting, lithium batteries, and industrial electronics. Key Highlights: Focused production line for NDT X-ray inspection equipment Fully integrated smart manufacturing and quality control systems Cutting-edge X-ray source development and testing facilities Customer-centric demo, sample testing service, and provided training We warmly invite our esteemed customers, partners, and distributors to join us on June 13, 2025, in Chongqing for this momentous celebration. Witness the future of non-destructive testing and explore new opportunities for collaboration and innovation. Kindly RSVP with your regional Unicomp representative. We look forward to welcoming you in Chongqing!

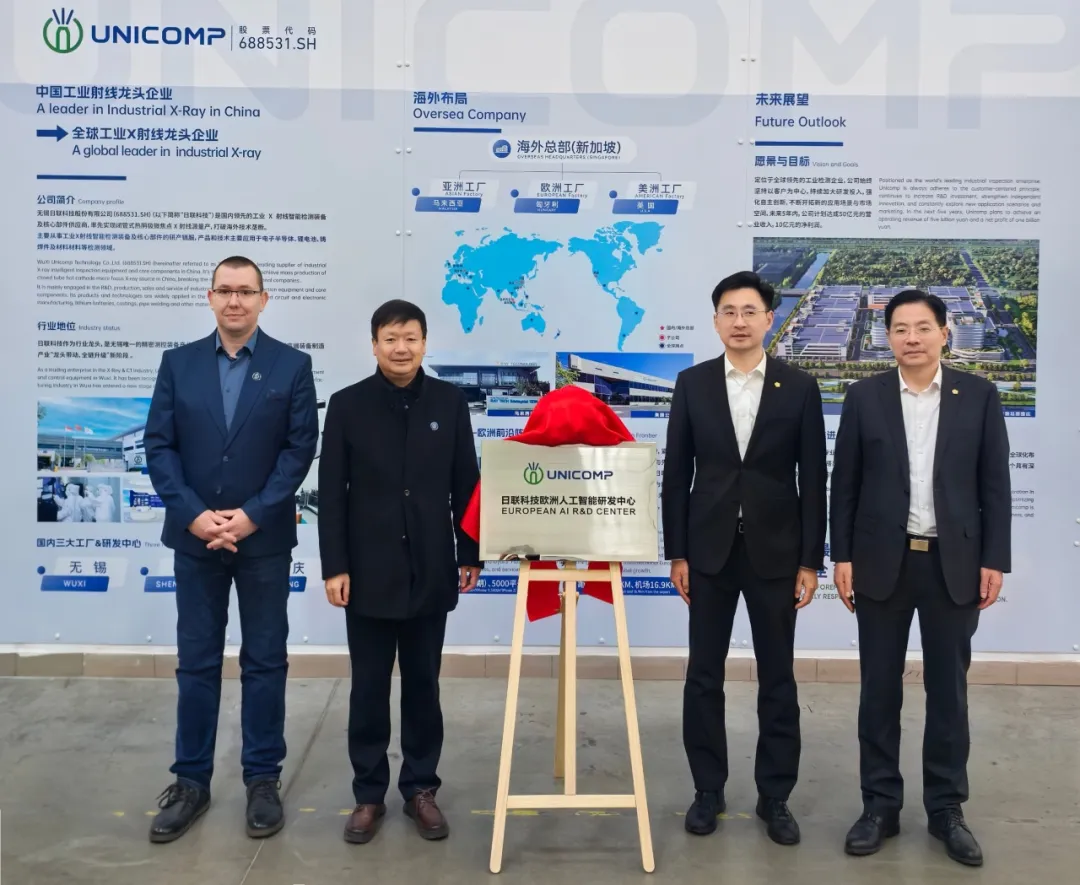

𝐀𝐜𝐜𝐞𝐥𝐞𝐫𝐚𝐭𝐢𝐧𝐠 𝐆𝐥𝐨𝐛𝐚𝐥 𝐄𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧 | 𝐔𝐧𝐢𝐜𝐨𝐦𝐩 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲’𝐬 𝐇𝐮𝐧𝐠𝐚𝐫𝐢𝐚𝐧 𝐒𝐮𝐛𝐬𝐢𝐝𝐢𝐚𝐫𝐲 𝐎𝐟𝐟𝐢𝐜𝐢𝐚𝐥𝐥𝐲 𝐎𝐩𝐞𝐧𝐬!

Unicomp Technology’s wholly owned subsidiary, Europe Unicomp Technology Kft., has officially opened in Budapest. This company is Unicomp Technology’s third overseas research and manufacturing base, following Malaysia and the United States. This move marks the company’s strategic shift into a new phase of “technology going global + local in-depth development.” Recently, the Wuxi Economic and Trade Delegation visited Hungary to attend the opening ceremony and to unveil Unicomp Technology’s “European Artificial Intelligence (AI) Research and Development Center.” The European AI R&D Center of Unicomp Technology will leverage the local scientific research ecosystem, focusing on innovations in intelligent detection algorithms. This will drive both localized adaptation of technology and global output, providing the core momentum to expand into high-end markets in Europe and the U.S., while helping China’s intelligent equipment reach the forefront of the global market. Hungary, located at the heart of Europe, is not only a hub for European manufacturing, with a mature automotive electronics industry cluster and supply chain system, but also attracts a large pool of high-end technical talent, offering a solid talent reserve in advanced manufacturing sectors. The establishment of Unicomp Technology’s subsidiary in Hungary is a proactive response to China’s Belt and Road Initiative, aiming to deepen European economic and trade cooperation, fully integrate Europe’s top talent resources and industrial capabilities, accelerate technological iteration and market response, and enhance global competitiveness.

𝐒𝐡𝐨𝐰𝐜𝐚𝐬𝐢𝐧𝐠 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐭𝐨 𝐎𝐯𝐞𝐫𝐬𝐞𝐚: 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡’𝐬 𝐏𝐚𝐫𝐞𝐧𝐭 𝐂𝐨𝐦𝐩𝐚𝐧𝐲, 𝐔𝐧𝐢𝐜𝐨𝐦𝐩’𝐬 𝐀𝐈 𝐗-𝐑𝐚𝐲 𝐒𝐡𝐢𝐧𝐞𝐬 𝐢𝐭𝐬 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧𝐬 𝐚𝐭 𝐇𝐮𝐧𝐠𝐚𝐫𝐲’𝐬 𝐈𝐧𝐧𝐨𝐄𝐥𝐞𝐜𝐭𝐫𝐨 𝐄𝐱𝐩𝐨

On April 8 to 10, 2025, the InnoElectro Expo — a premier event for the Central and Eastern European electronics industry — was held at the Budapest Congress and Exhibition Center. Organized by the Hungarian National Electronics Society, InnoElectro focuses on cutting-edge technologies in electronic components and embedded systems. It serves as a vital platform for trade and academic exchange within the Central and Eastern European electronics ecosystem. As an exhibitor (Booth: C04), Ray Tech’s parent company, Unicomp Technology showcased its leading-edge solutions built on over a decade of industrial cluster development and strategic location advantages. The company has established a oversea subsidiary in Hungary to better serve the European market. Unicomp’s Chairman Mr. Liu Jun personally attended the event to support his fellow team, while shown his exemplary leadership during the visit. At the show, Unicomp introduced its AI-powered, full-stack X-ray inspection solutions, tailored to deliver precision and efficiency in quality assurance for the electronics manufacturing sector. During the event, Unicomp’s international technical experts conducted an in-depth seminar on advancements in X-ray inspection technologies. Seizing new opportunities in global development, Unicomp is advancing its “Technology Export and Local Cultivation” strategies. With a manufacturing facility in Malaysia and subsidiaries in the United States, Hungary, and Singapore, the company is rapidly building a localized service infrastructure and strengthening its global collaboration network.

New Line of X-ray Machines, Revolutionizing Inspection TechnologyEvent

Product Launch Ray Tech (Malaysia) Sdn Bhd Launches New Line of X-ray Machines, Revolutionizing Inspection Technology Johor Bahru, Malaysia, 29 August 2024 – Ray Tech (Malaysia) Sdn Bhd, a leading innovator in micro-focus X-ray inspection technology, has unveiled its latest line of advanced X-ray inspection machines. This launch marks a pivotal moment for the company, showcasing its dedication to redefining precision inspection standards across various industries, including electronics, aerospace, and automotive sectors. The new product line integrates state-of-the-art imaging capabilities with enhanced user-friendly functionalities, allowing businesses to identify and rectify defects with unparalleled accuracy and efficiency. This advancement supports critical quality control processes and boosts productivity for clients worldwide. “This launch is a reflection of our steadfast commitment to innovation and quality,” said Mr. Matthew Loh, General Manager of Ray Tech (Malaysia) Sdn Bhd. “We aim to provide solutions that empower our clients to meet their quality goals, while positioning Ray Tech as a reliable partner for inspection excellence.” The newly developed machines feature groundbreaking micro-focus technology, capable of detecting even the most minute inconsistencies in materials and components. They are tailored to support modern manufacturing demands, helping companies maintain compliance with rigorous industry standards while minimizing operational downtime. Backed by a dedicated research and development team, Ray Tech continues to push the boundaries of what inspection technology can achieve. “ With this launch, we are taking significant strides toward expanding our presence in domestic and international markets ”, said Mr. Rudy Tan, Sales & Business Development Director of Ray Tech Singapore Pte Ltd. “We aim to become a trusted partner for businesses seeking reliable and precise inspection solutions.”

Ray Tech Chosen Johor as 1st Oversea Branch

Ray Tech (M) Sdn Bhd factory in SILC Industrial Park, Gelang Patah. | MDJ Nurina Aisyah’s photo A subsidiary of the Chinese technology giant Unicomp Technology China, Ray Tech (M) Sdn Bhd chose Johor as their new investment destination when they opened a factory related to X-Ray technology equipment in Taman Perindustrian SILC, Gelang Patah. More encouragingly, it is the first destination of the technology company’s manufacturing operations outside of mainland China.Dr. Liu Jun, President of Unicomp Technology Pte. Ltd, said that the decision to choose Johor as the company’s latest operating destination was based on careful planning and is confident that the state is the perfect location to further develop existing business potential.He said, Johor was chosen because it has a complete eco-system such as a sufficient supply chain where the company’s support suppliers are also located in the vicinity of Johor. In addition, its strategic position which is next to Singapore makes it easy for the company to export goods abroad and it is easy to get a skilled workforce in the field of mechanical, electrical and management through collaboration with local universities as one of the main factors that encourage the company, especially Ray Tech, to operate in the state this. Earlier, YAB Dato’ Onn Hafiz Ghazi, the Chief Minister of Johor was present to inaugurate the Official Opening Ceremony of Ray Tech (M) Sdn. Bhd., today. Also present were YB Lee Ting Han, Chairman of the Johor State Investment, Trade, Consumer Affairs and Human Resources Committee and YBhg. Siva Suriya Moorthy, Deputy Chief Executive Officer of the Malaysian Investment Development Authority (MIDA). For the record, until March 31, the Johor State Government has approved as many as 250 projects involving various sectors that are believed to be able to provide various returns in the form of economy such as job opportunities for the Johor people in particular. It thus shows the State Government’s commitment and seriousness in developing the Johor economy, thus realizing the goal of making Johor ‘The Next Shenzhen’.

Ray Tech(Malaysia) Sdn Bhd launches x-ray assembling operations in Johor. A milestone in high-tech industry development

In a historic moment for the high-tech industry, Ray Tech (Malaysia) Sdn Bhd celebrated the grand opening of its X-ray Assembling operations in Johor. The event, attended by esteemed members of the media, marked a significant milestone in the industrial landscape of Johor. With an initial investment of RM50 million, set to increase to RM150 million, Ray Tech’s foray into Johor signifies a strategic move towards establishing the state as a hub for high-tech industries. The company, a subsidiary of Unicomp Technology China, brings a legacy of innovation and expertise in X-ray technology to the region. Ray Tech’s state-of-the-art facility is poised to drive transformative changes in the industrial landscape, with a focus on sectors such as healthcare, electronics, semiconductors, and security. The company’s extensive range of high-end X-ray detection instruments caters to industries including Automotive, Lithium Battery, and Non-Destructive Testing. Moreover, Ray Tech’s collaboration with local educational institutions such as UTM, Southampton University, and Talent Corp underscores its commitment to nurturing local talent and fostering technological innovation. As Johor embarks on a new era of industrial growth and innovation, Ray Tech’s presence promises job creation, skills development, and economic advancements for the region. The company’s dedication to environmental stewardship sets a commendable example for sustainable industrial practices.