Innovative Precision with Micro-Focus

X-ray Technology

Achieve unmatched accuracy in inspection and quality control with our advanced Micro-Focus X-ray Technology. Engineered for industries from automotive to electronics, our solutions empower you to detect hidden flaws, ensure product reliability, and meet the highest standards with confidence.

20+

Years of Experience

Micro-focus

X-Ray Technology

Ray Tech’s vision is to be at the forefront of X-ray technology and become a recognized brand worldwide. Guided by this mission, we are committed to excellence in innovation, quality, and customer satisfaction.

In line with this, Ray Tech established its first overseas R&D and manufacturing plant in Malaysia in September 2023. The facility quickly gained UK BSI Certification with ISO45001, and its products comply with FDA standards and have received Radiation Permits, underscoring our adherence to global regulatory requirements.

To further expand our global reach, Ray Tech has set up its headquarters in Singapore, enabling us to better connect with international clients and provide superior customer services. With a firm commitment to becoming a globally recognized brand, we aim to lead the future of X-ray technology.

28+

Years of Experience

We are the leader in X-ray Products

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

- Duis aute irure dolor in reprehenderit

- Fwin voluptate velit esse cillum

- Globally Stable Partner

RayTech

X-Rays

Quality Materials

Experienced Team

Unique Technologies

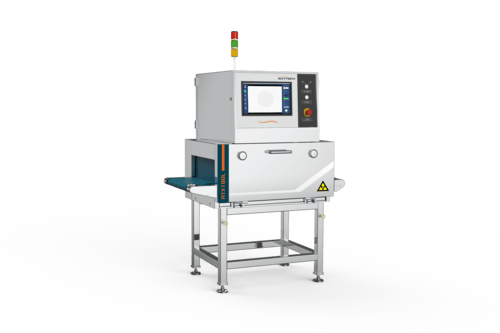

A Selection Of Products

We Serve

- All

- All Products

- Chip Counter X-Ray

- Electronic X-Ray

- Food Beverage X-Ray

- Industrial X-Ray

- Micro-focus X-Ray Source

- Semicon X-Ray

TIME HAS CHANGED

What are you

looking for?

The detector is the major part of the auto parts X-ray inspection system. It converts invisible X-rays into

visible light. Hence, it is possible to view the images easily through the naked eye. By sensing the intensity

of the X-ray beam passing through the object, the detector produces varied black and white values (gray

levels) on the image. That is why if the detector gets damaged, its replacement costs will be tremendous.

So, let us have a fair idea of how to select the right X-ray detector:

● Before choosing the detector, check for the best brand by searching via the internet.

● Check the flat detector of modern technology that can intensify the image.

● Try to select the amorphous silicon flat-panel detector.

● Do not opt for CMOS flat-panel digital detector.

Parameters of X-ray tube such as spatial resolution, target current, detail detectability, and focus port size

● Detector

● Geometric magnification

We have the right combination of the technical knowledge with qualified service expertise to provide proper maintenance service on our every X-ray system. If you have any query about our products or services, you can immediately contact us via online chat, phone, or email, so that our professional team will solve them at once.

1. Professional Service Team

Ray Tech has a team of well-experienced engineers to provide timely services for every customer, including consulting services, custom design, equipment qualification, safety inspection service, and so on.

2. Training & Maintenance Services

Ray Tech offers an exceptional range of after-sales services, such as online video instructions and installation guides for our customers to ensure that their new or existing equipment is in safe and good operating mode, with a long life cycle. Additionally, we provide prompt safety inspection with regular maintenance service as per the personalized needs of our customers. These services are also available for X-ray machines delivered by other suppliers.

3. Customized Services

Once when you share the application details to our team, we will recommend the best X-ray inspection solution for you. At times, a customized solution will be the best, where we’ll work with you to suggest the right X-ray machine that will meet all your requirements. Hence, you can contact our sales and support team to discuss our services at any time as per your convenience.

TESTIMONIALS

What Our Clients Say

"Since integrating Ray Tech's X-ray inspection equipment into our production line, we’ve noticed a significant improvement in quality control. The precision in detecting minute defects has been crucial for maintaining our industry standards. This technology has allowed us to minimize material waste and consistently deliver top- quality products to our clients."

"Ray Tech’s X-ray inspection system has transformed our food packaging process by ensuring every product meets the highest safety and quality standards. It detects even the smallest contaminants that could compromise product safety, giving us and our customers peace of mind. This system has not only streamlined our inspections but has also strengthened our brand’s reputation for reliable, safe products in the market."

RTX520

Product Features : The RTX520 is characterized by its attractive appearance, powerful functionality, and ease of operation. The software comes standard with Algorithms or image super-resolution reconstruction, improve image quality. Twin joysticks, X-Y & rotation control and Z Axis for titling & Magnification. Large size inspection table, with 360° rotation in both clockwise and counter clockwise

EXPLORE OUR

Latest Blogs

- Event

- Media

- Press Release

On 23 Feb, Ray Tech Malaysia Sdn Bhd officially resumes operations with a traditional firecracker ceremony to mark the beginning...

As we welcome the first day of the Year of the Horse, we wish you a year filled with “galloping”...

The Chinese New Year reunion dinner is the most important meal of the year. At Ray Tech Malaysia, we believe...