2025 marked a pivotal chapter in Ray Tech Malaysia’s journey — a year of consolidation, foundation-building, and strategic transformation. Under the leadership of our Group Vice President, Mr. James, and with the guidance of Chairman, Dr. Liu Jun, CEO, Mr. Ye, as well as our management vendor, Mr. Heng and senior advisor, Mr. Lim, we successfully established a local R&D team, built end-to-end X-ray system capabilities, and advanced multiple new products — laying a strong foundation for long-term sustainable growth. Throughout the year, our teams across R&D, Sales, Marketing, Operations, Supply Chain, Finance, HR, and Support functions worked in close collaboration — welcoming numerous customer visits and testing sessions, expanding our presence across international markets, and strengthening Ray Tech’s position as a trusted high-end X-ray inspection solutions provider. We are also honored to be recognized with the SME100 Award for Outstanding Performance and High Growth, a strong endorsement from the industry and market. As w𝐞 𝐥𝐨𝐨𝐤 𝐚𝐡𝐞𝐚𝐝 𝐭𝐨 𝟐𝟎𝟐𝟔, 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 𝐢𝐬 𝐬𝐞𝐭 𝐭𝐨 𝐞𝐧𝐭𝐞𝐫 𝐚 𝐧𝐞𝐰 𝐬𝐭𝐚𝐠𝐞 𝐨𝐟 𝐠𝐫𝐨𝐰𝐭𝐡 — 𝐝𝐫𝐢𝐯𝐞𝐧 𝐛𝐲 𝐢𝐧𝐝𝐞𝐩𝐞𝐧𝐝𝐞𝐧𝐭 𝐢𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧, 𝐀𝐈-𝐩𝐨𝐰𝐞𝐫𝐞𝐝 𝐗-𝐫𝐚𝐲 𝐢𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬, 𝐠𝐥𝐨𝐛𝐚𝐥 𝐦𝐚𝐫𝐤𝐞𝐭 𝐞𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧, 𝐚𝐧𝐝 𝐭𝐚𝐥𝐞𝐧𝐭 𝐝𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭. A heartfelt 𝐭𝐡𝐚𝐧𝐤 𝐲𝐨𝐮 𝐭𝐨 𝐨𝐮𝐫 𝐜𝐮𝐬𝐭𝐨𝐦𝐞𝐫𝐬, 𝐩𝐚𝐫𝐭𝐧𝐞𝐫𝐬, 𝐡𝐞𝐚𝐝𝐪𝐮𝐚𝐫𝐭𝐞𝐫𝐬 𝐚𝐧𝐝 𝐬𝐢𝐬𝐭𝐞𝐫 𝐜𝐨𝐦𝐩𝐚𝐧𝐢𝐞𝐬, 𝐦𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭 𝐭𝐞𝐚𝐦, 𝐚𝐧𝐝 𝐦𝐨𝐬𝐭 𝐢𝐦𝐩𝐨𝐫𝐭𝐚𝐧𝐭𝐥𝐲, 𝐞𝐯𝐞𝐫𝐲 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐭𝐞𝐚𝐦 𝐦𝐞𝐦𝐛𝐞𝐫 𝐚𝐧𝐝 𝐲𝐨𝐮𝐫 𝐟𝐚𝐦𝐢𝐥𝐢𝐞𝐬 for the unwavering support behind our success. Tonight, we 𝐩𝐫𝐨𝐮𝐝𝐥𝐲 𝐜𝐨𝐧𝐠𝐫𝐚𝐭𝐮𝐥𝐚𝐭𝐞 𝐨𝐮𝐫 𝐩𝐫𝐨𝐦𝐨𝐭𝐞𝐝 𝐜𝐨𝐥𝐥𝐞𝐚𝐠𝐮𝐞𝐬 𝐚𝐧𝐝 𝐚𝐰𝐚𝐫𝐝 𝐫𝐞𝐜𝐢𝐩𝐢𝐞𝐧𝐭𝐬. This achievement reflects not only your individual excellence, but also your positive impact on the team and the organization as a whole.

Author: admin

𝐏𝐨𝐬𝐢𝐭𝐢𝐨𝐧𝐢𝐧𝐠 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐟𝐨𝐫 𝟐𝟎𝟐𝟔: 𝐒𝐭𝐫𝐞𝐧𝐠𝐭𝐡𝐞𝐧𝐢𝐧𝐠 𝐆𝐥𝐨𝐛𝐚𝐥 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 𝐢𝐧 𝐗-𝐑𝐚𝐲 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬 𝐚𝐜𝐫𝐨𝐬𝐬 𝐒𝐞𝐦𝐢-𝐜𝐨𝐧, 𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐧𝐢𝐜𝐬, 𝐍𝐃𝐓, 𝐀𝐮𝐭𝐨𝐦𝐨𝐭𝐢𝐯𝐞, 𝐅𝐨𝐫𝐞𝐢𝐠𝐧 𝐎𝐛𝐣𝐞𝐜𝐭 𝐃𝐞𝐭𝐞𝐜𝐭𝐢𝐨𝐧 𝐢𝐧 𝐅&𝐁 𝐚𝐧𝐝 𝐋𝐢𝐭𝐡𝐢𝐮𝐦 𝐁𝐚𝐭𝐭𝐞𝐫𝐲

5 January marked an important milestone as Ray Tech Malaysia convened its Annual Townhall Meeting, bringing together management and team members to review performance, reinforce strategic alignment, and define the direction ahead. The townhall featured keynote addresses from the company’s senior leadership: • 𝐌𝐫 𝐉𝐚𝐦𝐞𝐬 𝐋𝐞𝐞, 𝐆𝐫𝐨𝐮𝐩 𝐕𝐢𝐜𝐞 𝐏𝐫𝐞𝐬𝐢𝐝𝐞𝐧𝐭 𝐜𝐮𝐦 𝐆𝐞𝐧𝐞𝐫𝐚𝐥 𝐌𝐚𝐧𝐚𝐠𝐞𝐫 • 𝐌𝐫 𝐀𝐥𝐚𝐧 𝐁𝐨𝐨𝐧, 𝐃𝐢𝐫𝐞𝐜𝐭𝐨𝐫 𝐜𝐮𝐦 𝐎𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐌𝐚𝐧𝐚𝐠𝐞𝐫 • 𝐌𝐫 𝐉𝐚𝐜𝐤 𝐘𝐚𝐧𝐠, 𝐃𝐞𝐩𝐮𝐭𝐲 𝐆𝐞𝐧𝐞𝐫𝐚𝐥 𝐌𝐚𝐧𝐚𝐠𝐞𝐫 𝐜𝐮𝐦 𝐑&𝐃 𝐃𝐢𝐫𝐞𝐜𝐭𝐨𝐫 • 𝐌𝐫 𝐇𝐞𝐧𝐠, 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭 𝐌𝐞𝐧𝐭𝐨𝐫 The session formally concluded the year 2025, a year marked by strong strategic execution and organizational progress. Ray Tech successfully achieved overseas market expansion , strengthened its brand positioning, and continued to advance new product development initiatives through innovation and research. From an operational standpoint, a major milestone was reached with the successful implementation of full X-Ray equipment development assembly in Malaysia, supported by increased adoption of local comprehensive supply chain . This achievement reinforces Ray Tech’s commitment to manufacturing excellence, supply chain resilience, and long-term localization strategy. Most importantly, a clear and unified strategic direction was communicated, ensuring alignment across departments and empowering teams to move forward with clarity, confidence, and shared objectives. In closing, Ray Tech Malaysia’s continued growth is supported by the strong foundation of our parent company, Unicomp Group. With major R&D and manufacturing operations in Wuxi, Shenzhen, and Chongqing , as well as a strategic European showroom in Hungary , the Group enables Ray Tech to deliver advanced X-ray inspection solutions to customers across global markets. As we look ahead to 2026, Ray Tech Malaysia, together with Unicomp Group, remains focused on innovation, globalization, and sustainable growth, driven by strong leadership and a shared long-term vision.

𝐓𝐞𝐜𝐡 𝐆𝐢𝐚𝐧𝐭𝐬 𝐈𝐧𝐯𝐞𝐬𝐭 𝐁𝐢𝐥𝐥𝐢𝐨𝐧𝐬 𝐢𝐧 𝐉𝐨𝐡𝐨𝐫’𝐬 𝐃𝐚𝐭𝐚 𝐂𝐞𝐧𝐭𝐫𝐞 𝐄𝐜𝐨𝐬𝐲𝐬𝐭𝐞𝐦 — 𝐌𝐚𝐬𝐬𝐢𝐯𝐞 𝐈𝐧𝐯𝐞𝐬𝐭𝐦𝐞𝐧𝐭𝐬 𝐅𝐚𝐜𝐞 𝐚 𝐂𝐫𝐢𝐭𝐢𝐜𝐚𝐥 𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞

Johor has rapidly positioned itself as Malaysia’s leading data centre hub, drawing multi-billion-ringgit investments from global technology leaders. As hyperscale facilities expand across the Johor–Singapore corridor, a critical challenge emerges: How can data centre equipment—servers, high-performance chips, PCs, cooling systems, and electronic modules—maintain long-term stability, operational reliability, and energy efficiency under continuous 24/7 workloads? Undetected internal defects, even at a microscopic level, can lead to faulty function issues, performance degradation, and unplanned downtime. Ensuring reliability begins at the component and assembly stage. Advanced X-ray inspection enables early detection of internal defects such as voids, cracks, solder joint abnormalities, and structural misalignments—preventing latent failures before equipment enters mission-critical environments. Ray Tech Malaysia supports this requirement through Unicomp X-ray inspection solutions specially designed for the semiconductor and electronics industries: AX9100Max – Flagship High-resolution X-ray system for advanced server boards, high-layer PCBAs, power modules, and dense semiconductor packaging, delivering deep penetration and precise defect analysis. AX8300 Plus – High-precision micro-focus X-ray inspection for fine-pitch components, BGA, QFN, and complex PCBA assemblies widely used in data centre electronics. AX8200Max – Versatile offline X-ray inspection solution for detailed quality verification, failure analysis, and process optimization in electronics manufacturing. AX7900 – Compact and efficient X-ray inspection system for routine quality control, incoming inspection, and engineering analysis while maintaining reliable detection capability.

𝐆𝐨𝐨𝐝𝐛𝐲𝐞 𝟐𝟎𝟐𝟓, 𝐖𝐞𝐥𝐜𝐨𝐦𝐞 𝟐𝟎𝟐𝟔

At Ray Tech Malaysia, we are grateful for the trust and long-term relationships with our dearest distributors, clients and staff built over the years. 2026 marks a new chapter of innovation and growth—together. Happy New Year to all.

𝐖𝐞 𝐰𝐞𝐫𝐞 𝐡𝐨𝐧𝐨𝐫𝐞𝐝 𝐭𝐨 𝐰𝐞𝐥𝐜𝐨𝐦𝐞 𝐃𝐫. 𝐖𝐚𝐧 𝐅𝐚𝐡𝐦𝐢𝐧 𝐚𝐧𝐝 𝐭𝐡𝐞 𝐅𝐚𝐜𝐮𝐥𝐭𝐲 𝐨𝐟 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠, 𝐔𝐧𝐢𝐯𝐞𝐫𝐬𝐢𝐭𝐢 𝐓𝐞𝐤𝐧𝐨𝐥𝐨𝐠𝐢 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 (𝐔𝐓𝐌) 𝐭𝐨 𝐭𝐡𝐞 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 𝐟𝐚𝐜𝐭𝐨𝐫𝐲.

The visit provided valuable opportunities for knowledge exchange, industry insights, and collaboration between academia and industry in advancing engineering and inspection technologies.

𝐅𝐢𝐫𝐞 𝐄𝐦𝐞𝐫𝐠𝐞𝐧𝐜𝐲 𝐄𝐯𝐚𝐜𝐮𝐚𝐭𝐢𝐨𝐧 𝐃𝐫𝐢𝐥𝐥

Regular drills help us stay prepared, calm, and responsive in real emergencies. At Ray Tech Malaysia, safety is not just a procedure — it’s a responsibility. We warmly welcome our dearest distributers and customers to drop by and explore our latest X-ray inspection solutions in a brand new environment!

“𝐏𝐫𝐞𝐯𝐞𝐧𝐭𝐢𝐧𝐠 𝐇𝐢𝐝𝐝𝐞𝐧 𝐅𝐨𝐨𝐝 𝐂𝐨𝐧𝐭𝐚𝐦𝐢𝐧𝐚𝐧𝐭𝐬: 𝐒𝐚𝐟𝐞𝐠𝐮𝐚𝐫𝐝𝐢𝐧𝐠 𝐒𝐚𝐟𝐞𝐭𝐲 𝐰𝐢𝐭𝐡 𝐔𝐍𝐈𝐂𝐎𝐌𝐏 𝐗-𝐑𝐚𝐲 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲”

A recent incident in Singapore highlighted the critical importance of food safety when a diner was injured after biting into cooked fish containing a 𝟐.𝟓 𝐜𝐦 𝐟𝐢𝐬𝐡 𝐡𝐨𝐨𝐤, initially mistaken for a fish bone. While the restaurant apologised and compensated the customer, the case underscores the potential hazards of hidden foreign objects in food, which can pose serious health risks and damage consumer trust To prevent such incidents, Ray Tech Malaysia offers advanced UNICOMP Food X-ray Inspection Solutions, designed to detect metal, bones, hooks, glass, stones, and other dense foreign objects in a wide range of food products — including cooked, packaged, and bulk items. Key solutions include: • UNICOMP 𝐔𝐍𝐗𝟏𝟖𝟑𝟎 – Specialised for bottles and cans, detecting foreign objects without opening or damaging the container. • UNICOMP 𝐔𝐍𝐗𝟒𝟎𝟏𝟓 – Ideal for packed, bagged, and boxed foods, ensuring safety and quality across small to medium-sized packaged products. • UNICOMP 𝐔𝐍𝐗𝟔𝟎𝟑𝟎 – Designed for larger items and bulk packaging, such as seafood and frozen foods, providing reliable detection without affecting product integrity. By integrating X-ray inspection into production and packaging lines, food manufacturers can significantly enhance consumer safety, regulatory compliance, and brand confidence, minimizing the risk of incidents like the recent fish hook case. Message us today to schedule your demonstration or request a consultation!

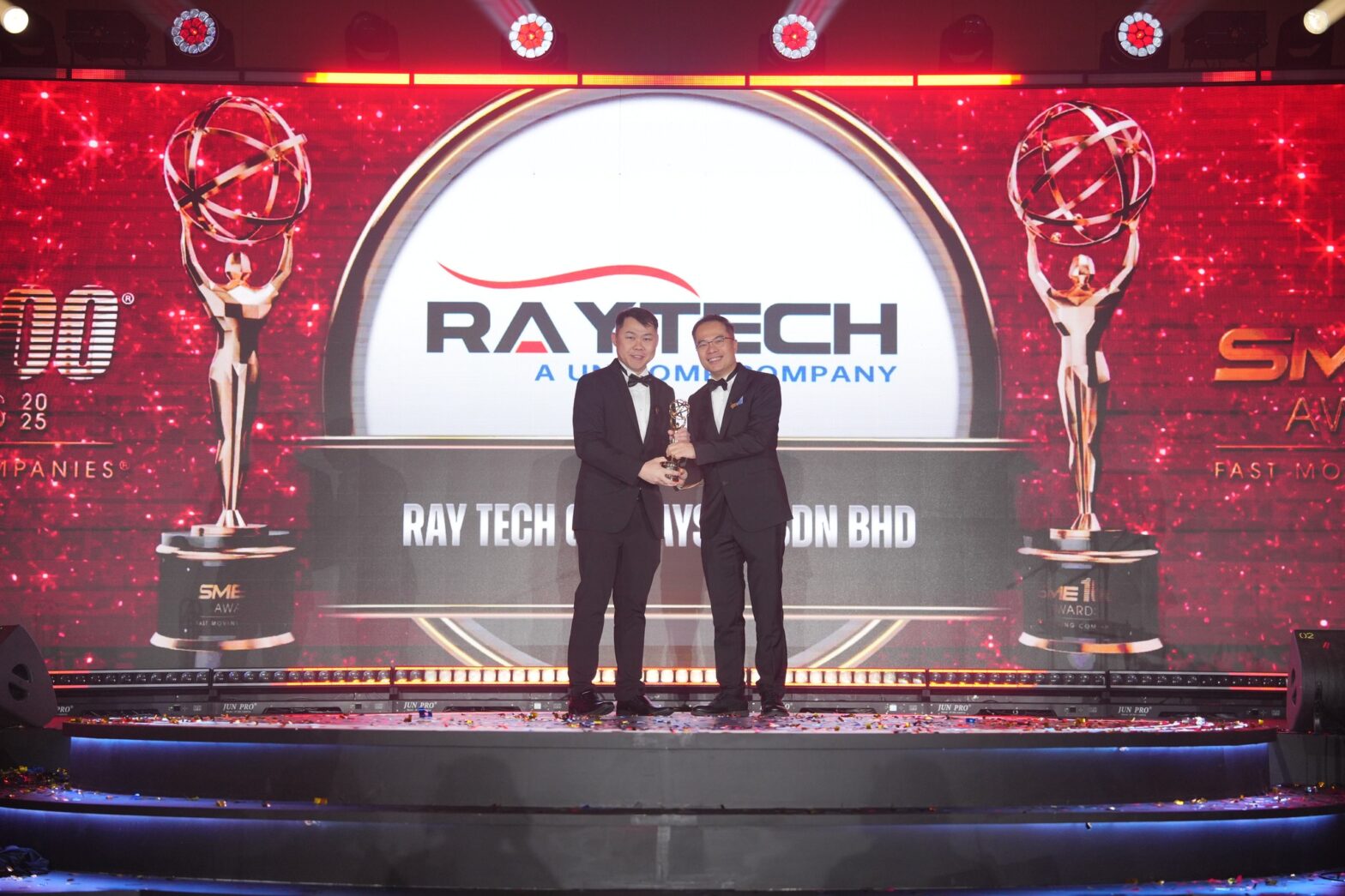

𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 𝐀𝐰𝐚𝐫𝐝𝐞𝐝 𝐢𝐧 𝐭𝐡𝐞 𝐏𝐫𝐞𝐬𝐭𝐢𝐠𝐢𝐨𝐮𝐬 𝐒𝐌𝐄𝟏𝟎𝟎 𝐅𝐚𝐬𝐭 𝐌𝐨𝐯𝐢𝐧𝐠 𝐂𝐨𝐦𝐩𝐚𝐧𝐢𝐞𝐬 𝐂𝐚𝐭𝐞𝐠𝐨𝐫𝐲

Ray Tech (Malaysia) Sdn Bhd, the subsidiary of Unicomp Technology (Group) Co., Ltd. has been proudly named a winner of the 2025 SME100 Awards – Fast Moving Companies, emerging among Malaysia’s top high-growth enterprises. This achievement reflects the company’s strong overall performance in business operations, technological innovation, talent development, market expansion, and global strategic execution. 𝟏. 𝐀𝐛𝐨𝐮𝐭 𝐒𝐌𝐄𝟏𝟎𝟎|𝐎𝐧𝐞 𝐨𝐟 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚’𝐬 𝐌𝐨𝐬𝐭 𝐑𝐞𝐬𝐩𝐞𝐜𝐭𝐞𝐝 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐀𝐜𝐜𝐨𝐥𝐚𝐝𝐞𝐬 The SME100 Awards were established by SME Magazine, one of Southeast Asia’s most influential business media platforms. Endorsed by the Ministry of Finance Malaysia and co-developed with Credit Bureau Malaysia in 2009, SME100 has grown into one of the region’s most credible, authoritative, and widely recognized awards for emerging enterprises. The award adopts a strict and comprehensive evaluation methodology, assessing companies in areas such as: • Business growth and financial performance • Local talent development and regional expansion • Innovation capability and investment in technology • Internal controls and risk management • Brand strength and market competitiveness • Global strategy and corporate governance The assessment involves an independent audit, data verification, management interviews, and on-site evaluation, ensuring a transparent, objective, and highly rigorous selection process. Because of its high standards, SME100 is widely regarded as a benchmark for high-quality enterprise growth in Southeast Asia. 𝟐. 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 𝐄𝐱𝐜𝐞𝐥𝐥𝐞𝐧𝐜𝐞|𝐆𝐮𝐢𝐝𝐞𝐝 𝐛𝐲 𝐌𝐫 𝐉𝐚𝐦𝐞𝐬 𝐋𝐞𝐞 𝐓𝐨𝐰𝐚𝐫𝐝 𝐍𝐞𝐰 𝐇𝐞𝐢𝐠𝐡𝐭𝐬 Ray Tech Malaysia’s success in earning the SME100 Fast Moving Companies Award is closely tied to the leadership of Mr James Lee, Vice President of Unicomp Technology Group and Director cum General Manager of Ray Tech Malaysia. Through multiple rounds of strategic presentations to the evaluation committee, Mr James highlighted the company’s: • Clear and disciplined management principles • Strong talent development ecosystem • Forward-looking innovations in industrial AI and intelligent inspection • Strategic positioning and long-term roadmap in the Southeast Asian market His ability to articulate Ray Tech’s vision, technological strengths, market strategy, and future development plans earned high appreciation from the judging panel. This award signifies not only Ray Tech Malaysia’s rapid growth but also its capacity for sustained innovation, operational excellence, and long-term competitiveness. 𝟑. 𝐀𝐛𝐨𝐮𝐭 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚|𝐀𝐝𝐯𝐚𝐧𝐜𝐢𝐧𝐠 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐗-𝐫𝐚𝐲 𝐚𝐧𝐝 𝐀𝐈-𝐃𝐫𝐢𝐯𝐞𝐧 𝐈𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 Ray Tech (Malaysia) Sdn Bhd is the wholly owned Malaysian subsidiary of Unicomp Technology Group, China’s leading provider of industrial X-ray and intelligent inspection technologies. The company specializes in AI-powered industrial X-ray inspection equipment, application engineering, technical training, and after-sales services. Its technologies are widely applied in: • Semiconductor packaging and advanced assembly • Electronics manufacturing & SMT • Automotive and EV component inspection • Die-cast and precision parts • Lithium battery safety and quality inspection • Industrial manufacturing quality control • Food and FMCG foreign-object detection Ray Tech operates a comprehensive technical and applications facility in Johor, offering: • Equipment demonstrations • Sample testing & data analysis • Application validation • After-sales support • Customer and engineer training This allows Ray Tech to deliver fast, professional, and end-to-end inspection solutions for Malaysian and Southeast Asian manufacturers. With continuous investment in technology, services, and application expertise, Ray Tech has achieved steady market expansion and strong brand recognition, becoming one of Malaysia’s leading industrial inspection solution providers. 𝟒. 𝐀𝐰𝐚𝐫𝐝 𝐂𝐞𝐫𝐞𝐦𝐨𝐧𝐲|𝐌𝐫. 𝐀𝐥𝐚𝐧 𝐁𝐨𝐨𝐧, 𝐓𝐡𝐞 𝐑𝐞𝐩𝐫𝐞𝐬𝐞𝐧𝐭𝐚𝐭𝐢𝐯𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐆𝐫𝐨𝐮𝐩 At the awards ceremony, Mr. Alan Boon, Director and Operations Manager of Ray Tech Malaysia, accepted the “Fast Moving Companies Award” on behalf of Mr James Lee. This recognition reinforces the achievements of Unicomp Technology Group’s Southeast Asia expansion, the dedication of its global workforce, and the ongoing trust and support of customers and partners across the region.

𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐝 𝐚𝐬 𝐊𝐞𝐲 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐏𝐚𝐫𝐭𝐧𝐞𝐫 𝐚𝐭 𝐔𝐓𝐌’𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐓𝐚𝐥𝐤

Ray Tech Malaysia, the subsidiary of Unicomp Technology Group in Malaysia —a global leader in industrial X-ray inspection technology—was honoured to be invited by Universiti Teknologi Malaysia (UTM) to deliver an industrial talk to students from the Faculty of Science, reinforcing the university’s ongoing efforts to strengthen industry–academia collaboration. Represented by Sales Manager Mr. Edward Tang and HR Manager Ms. Yiau Sok Fang, Ray Tech presented an insightful and impactful session showcasing the rapid advancements and real-world applications of industrial X-ray inspection technology. The talk highlighted how X-ray systems have become a critical foundation of modern high-tech industries, supporting: • Semiconductor manufacturing inspect solution • Electronics reliability and quality assurance • Automotive and EV component safety • Lithium battery safety evaluation • Food and FMCG foreign-object detection Students gained a deeper understanding of how these technologies ensure product safety, improve manufacturing efficiency, and shape the innovation landscape across Malaysia, ASEAN, and the global industry. 𝐒𝐮𝐩𝐩𝐨𝐫𝐭𝐢𝐧𝐠 𝐔𝐓𝐌 𝐓𝐚𝐥𝐞𝐧𝐭 𝐖𝐢𝐭𝐡 𝐅𝐮𝐭𝐮𝐫𝐞 𝐂𝐚𝐫𝐞𝐞𝐫 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐢𝐞𝐬 During the session, Ray Tech also emphasised its commitment to supporting UTM’s talent pipeline, particularly students from the Faculty of Science, by offering various career and internship opportunities within the rapidly growing X-ray inspection and advanced manufacturing ecosystem. The company aims to provide graduates with meaningful pathways to enter high-value industries, equipping them with the skills, exposure, and technical understanding required to excel in today’s competitive technology-driven environment. Through this engagement, Ray Tech hopes to inspire future scientific and engineering talent, enhance students’ industry awareness, and further drive long-term partnerships between academia and industry—continuously contributing to the region’s technological growth and innovation leadership.

𝐀𝐬 𝐩𝐚𝐫𝐭 𝐨𝐟 𝐔𝐓𝐌’𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐚𝐧𝐝 𝐂𝐚𝐫𝐞𝐞𝐫 𝐓𝐚𝐥𝐤𝐬, 𝐑𝐚𝐲 𝐓𝐞𝐜𝐡 𝐌𝐚𝐥𝐚𝐲𝐬𝐢𝐚 𝐰𝐢𝐥𝐥 𝐛𝐞 𝐬𝐡𝐚𝐫𝐢𝐧𝐠 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐢𝐧𝐭𝐨 𝐭𝐡𝐞 𝐫𝐨𝐥𝐞 𝐨𝐟 𝐚𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐗-𝐫𝐚𝐲 𝐢𝐧𝐬𝐩𝐞𝐜𝐭𝐢𝐨𝐧 𝐬𝐲𝐬𝐭𝐞𝐦𝐬 𝐢𝐧 𝐭𝐨𝐝𝐚𝐲’𝐬 𝐡𝐢𝐠𝐡-𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐢𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐞𝐬.

Our Sales Manager, Mr. Edward Tang, will present how X-ray technology drives innovation across semiconductors, electronics, automotive, smart mobile devices, foreign object detection in food safety and more. We look forward to engaging with students from all years and supporting their exposure to real-world industrial applications.