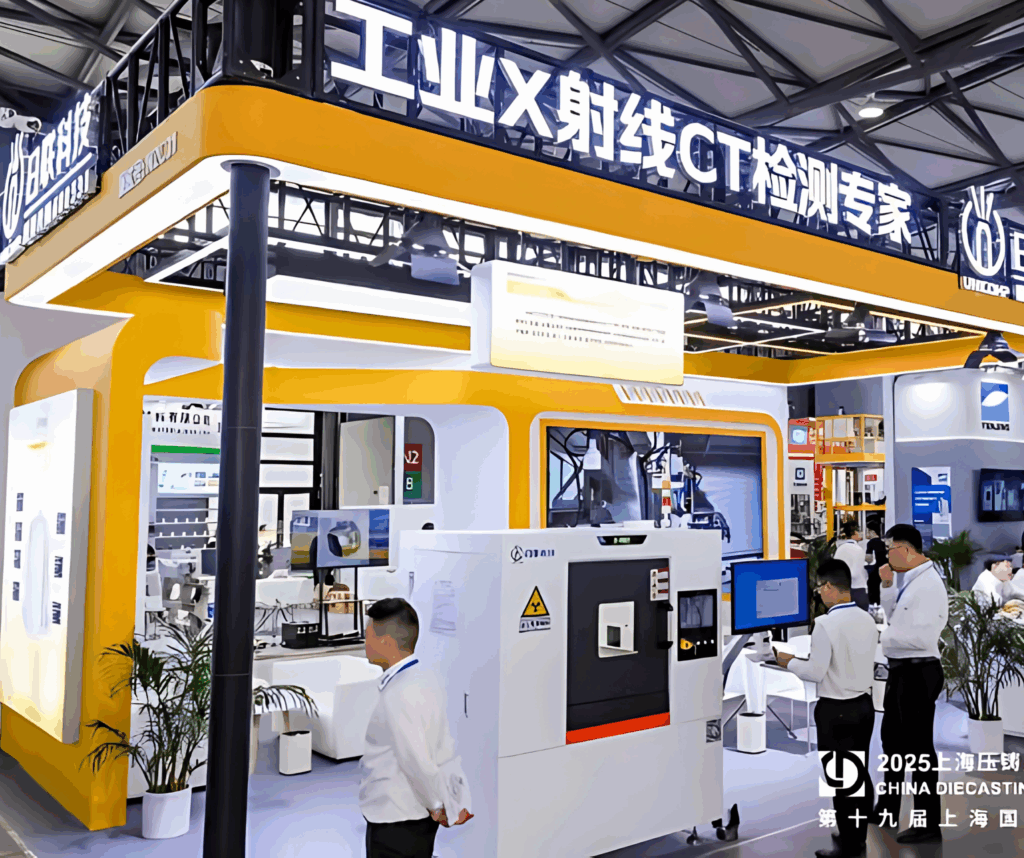

July 16, 2025 – The 19th Shanghai International Die Casting and Nonferrous Foundry Exhibition officially opened at the Shanghai New International Expo Centre. As a premier global event in the die casting industry, the exhibition brings together cutting-edge technologies and groundbreaking innovations from around the world.

01 Addressing Industry Pain Points | Breaking Through Internal Defect Detection Barriers

During the die casting process, accurate detection of internal defects—such as porosity, shrinkage, and cracks—is critical for ensuring product quality. However, this remains a recognized technical challenge in the industry. Traditional inspection methods have notable limitations:

- Limited Accuracy: Ineffective at identifying and locating small, deeply embedded internal defects.

- Efficiency Bottlenecks: Reliance on manual interpretation slows down the inspection process and increases the risk of missed defects.

- Lack of Data: Inability to provide precise 3D spatial information or quantitative data of defects, hindering process optimization and traceability.

02 Intelligent CT Solution | A Full-Stack Detection Approach

Ray Tech Malaysia’s parent company, Unicomp Technology Group’s showcased solution integrates high-precision X-ray computed tomography (CT) with AI-driven algorithms, offering the following core capabilities:

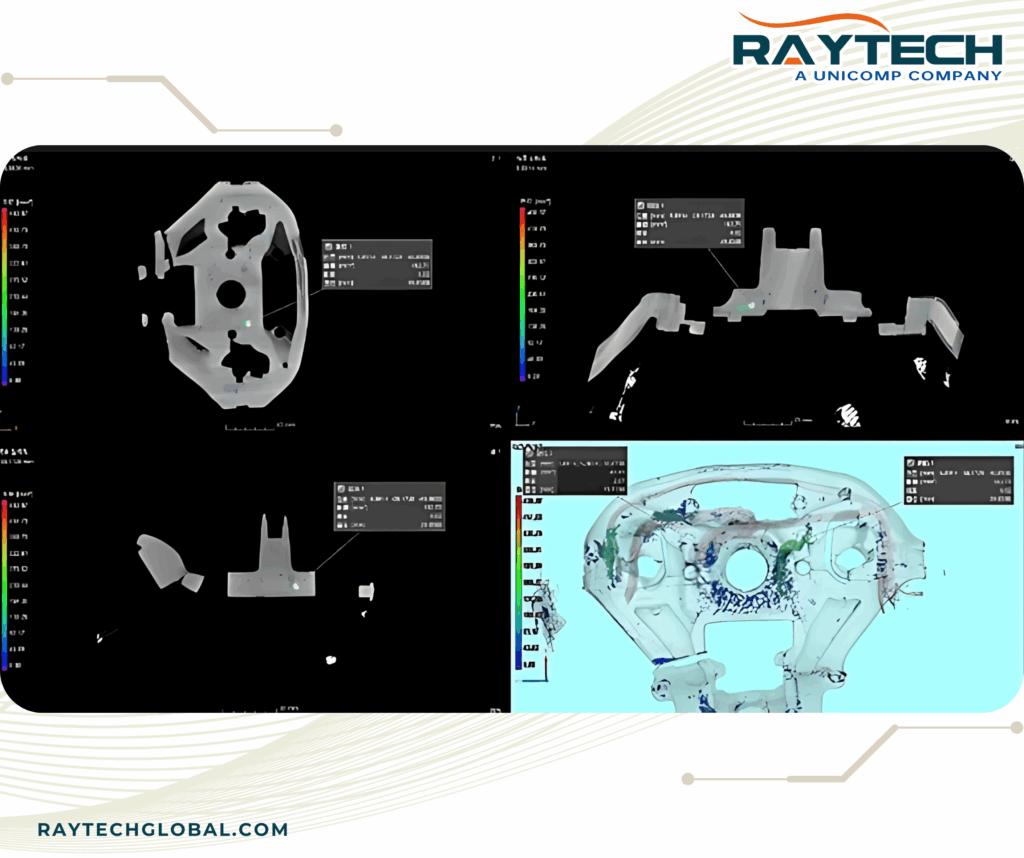

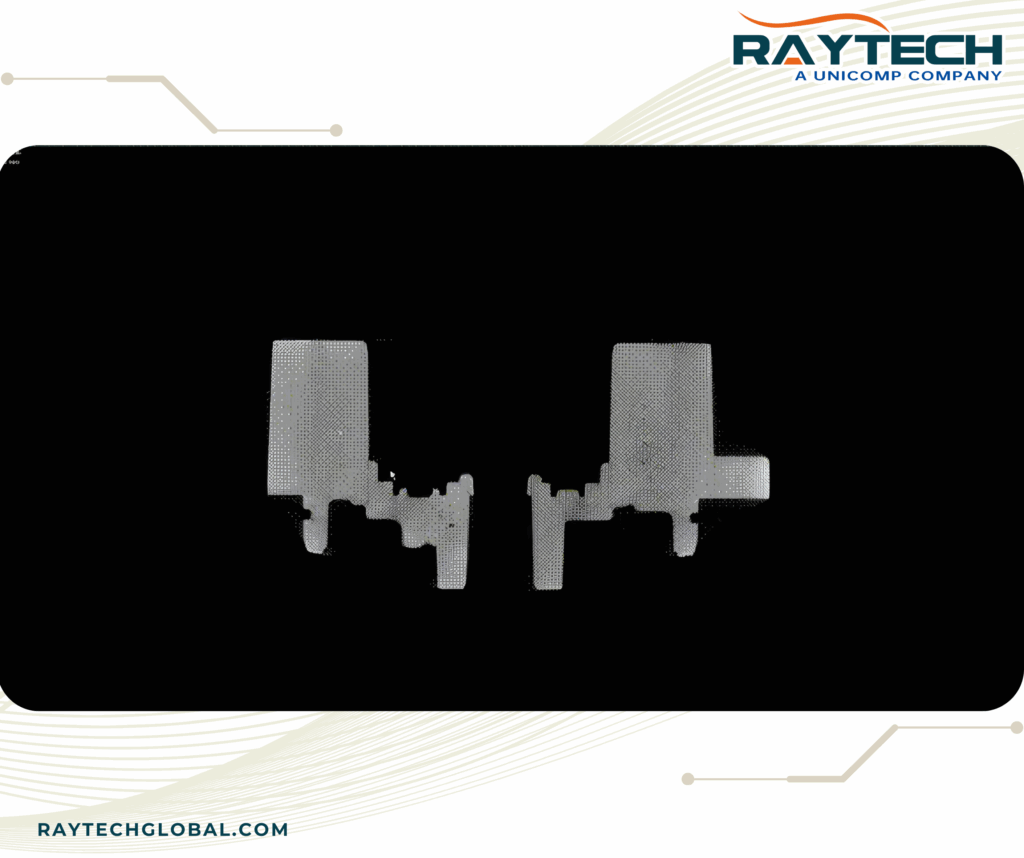

2.1 3D Imaging Visualization

Using high-resolution X-ray scanning, the system rapidly reconstructs a complete 3D model of the workpiece’s internal structure. It clearly visualizes various internal defects—such as porosity, inclusions, and cracks—while accurately locating them in 3D space.

- 2.2 High-Resolution Detail Presentation

The system delivers outstanding spatial resolution, enabling magnified imaging of critical areas like fine structural edges and crack tips. Even micron- and nano-level defect features can be clearly observed.

- 2.3 AI-Powered Automated Analysis

Equipped with an intelligent defect recognition system, the solution automatically detects and analyzes common casting defects. It generates visual, data-rich reports detailing defect location, size, quantity, and type. This provides a strong foundation for closed-loop quality control across detection, analysis, and process optimization.

03 Technology Showcase Draws Attention | Dynamic On-Site Engagement

On the opening day, Unicomp Technology Group’s booth attracted a large number of technical professionals and decision-makers across the die casting supply chain. The technical team engaged in in-depth discussions with visitors, offering live equipment demonstrations and detailed explanations of application scenarios and pain point solutions.

According to public information, Unicomp Technology has a strong track record in the X-ray inspection field, with over 600 core patents and intellectual property certifications. Its solutions are deployed in more than 70 countries and regions, with over 30,000 successful application cases to date.

Unicomp Technology Group cordially invites all die casting professionals to connect and collaborate. We remain committed to advancing quality inspection technologies, helping manufacturers enhance precision and efficiency in quality control, and strengthening global competitiveness. Let’s explore innovations and shape the future of the industry—together.